Practical insights into resistivity measurements

This article covers some fundamentals, practical tips, and pitfalls related to the resistance and resistivity measurements of electrically conductive plastics. To achieve the most precise outcome, it is essential that you understand the basic measurement procedure and the key factors causing uncertainties in measurements. In this way, the probability of errors will be decreased, and analyzing the outcome of the measurement will be easier.

Fundamentals and definitions – the dependency between resistivity and resistance

Resistance and resistivity describe the ability of the material or the object to impede the flow of current passing through it.

Resistivity (ρ) relates to the electric properties of the material. Resistivity is a characteristic of the material and is not dependent on the dimensions of the measured material sample. The SI-unit for volume resistivity is [Ωm] or [Ωcm] and for surface resistivity [Ω].

Resistance (R) describes an object’s ability to resist electrical current in a measurement circuit. Resistance is dependent on the dimensions of the object and the electrode. The SI-unit for resistance is Ω, which describes the ratio of voltage across the object to the current through the object (R = U/I = [V/A]).

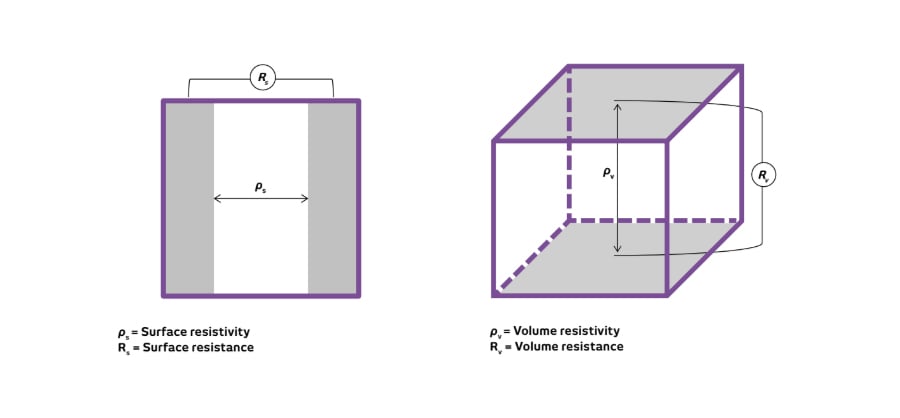

Surface resistance or resistivity describes the resistance to the current passing through the material's surface or object. Volume resistance or resistivity takes into account the volume of the object and describes the resistance to the current passing through the material or object.

The following example illustrates the correlation between resistance and resistivity:

If surface resistance of 1 cm x 1 cm solid surface is 1 Ω, the resistivity of the material is [Ω · cm / cm] = [Ω]. If volume resistance of a 1 cm x 1 cm x 1 cm solid cube is 1 Ω, the resistivity of the material is [Ω · cm · cm / cm] = [Ωcm].

Eliminate the factors causing uncertainties. In practice, certain uncertainties are unavoidable when measuring resistivity. These uncertainties can be caused by the measurement device, measuring setup, or external factors. Typically they have a significant effect on the outcome of the measurement. Measurement errors can be orders of magnitude. A practical way to evaluate the accuracy of the measurement result is to repeat the measurement with different electrodes and observe the deviation in the measurement results. The best measurement method will lead to the smallest deviation in results. In this chapter, we introduce three factors that have a major impact on measurement accuracy and results.

1. Contact between the electrode and test sample

Contact resistance may cause remarkable systematic errors in case only one measurement method is in use. One cannot detect it without carrying out parallel measurements with another electrode type. The material and size of the electrode also matter: the electrode type should be selected so that the entire electrode is in contact with the sample. For example, most metallic electrodes ensure good and uniform contact only with other metallic samples. For plastic samples, soft conductive rubber electrodes are a better choice, as the soft material enables better contact with the plastic surface.

Use an electrode that measures

the lowest resistance values.

The contact resistance between the sample and the electrode is typically higher than the material's resistance being tested. Use the electrode which measures the lowest resistance values.

2. Measurement range and voltage

The measurement range should be considered separately for each measurement. The range depends on the limits of the test method, instrumentation, and properties of a target to be measured.

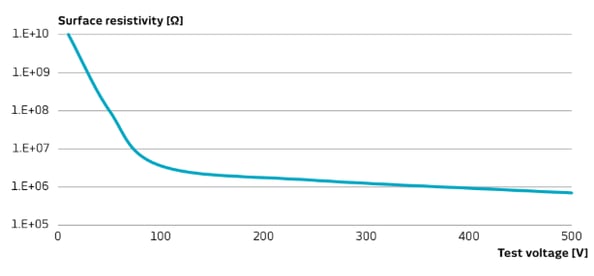

Figure 1 — Voltage dependency curve for the surface resistivity of a carbon black-based static dissipative compound (ring electrode)

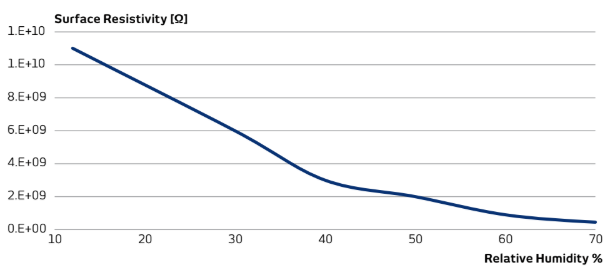

Figure 2 — Humidity dependency curve for the surface resistivity of a carbon black-based static dissipative compound (ring electrode)

The measured resistance value depends significantly on the used voltage levels. Some voltage meters adjust the measurement voltage automatically. For static dissipative materials (surface resistance > 1E5 Ω), the measurement voltage is 100 V, and 10 V for electrically conductive plastics (surface resistance ≤ 1E5 Ω).

An example of voltage dependency is shown in figure 1 (above). Every sample and electrode forms a unique combination in terms of contact resistance. This is why you cannot anticipate or build a model for the voltage dependency of specific materials or samples. Relatively high test voltage may cause high power consumption and heating in an inhomogeneous resistive path.

In this case, resistance may remain low after heating even if the measurement is repeated with the lower voltage.

3. Environmental conditions

In the material qualification phase, measurements should be carried out in a laboratory – preferably in a controlled environment, humidity 12 % ± 3 % (or 25 %) and temperature 23 ̊C.

The samples and electrode should also be conditioned for 48 hours before the measurement. When measurements are carried outside the laboratory, the humidity and temperature must also be recorded before and during the measurement. Humidity has a significant effect on the results. Higher humidity enables better contact between the sample and the electrode and leads to lower resistance values (see figure 2 above).

Follow the measurement procedure

It is a good idea to go through the operating manual of your measurement device before making any measurements. Here are some general guidelines for resistance and resistivity measurements:

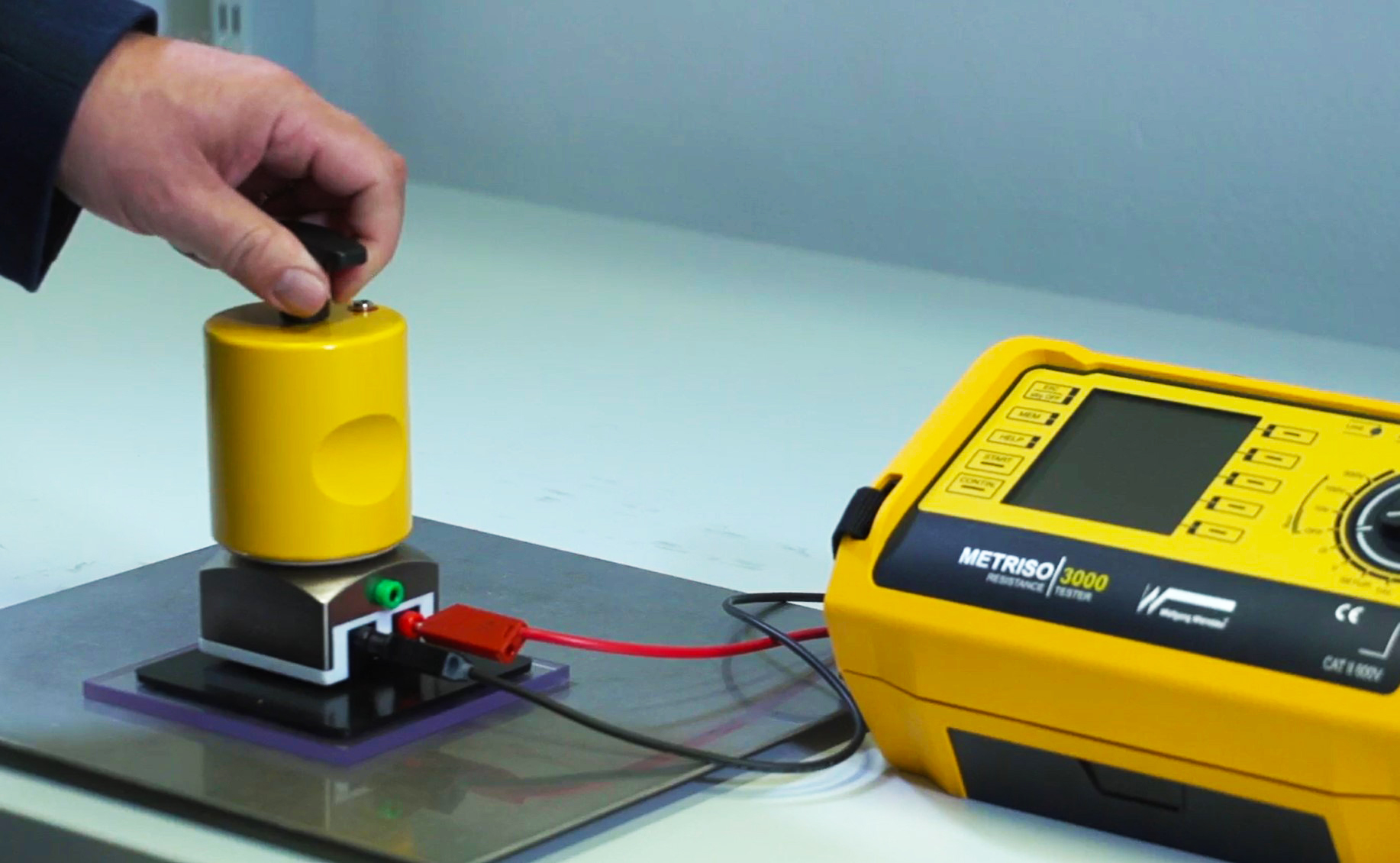

- Choose the best measuring method (point-to-point resistance/standardized surface resistance/surface resistivity/volume resistivity) and electrode (ring/bulk/finger electrode) for the purpose.

- Set up the instrumentation according to the measurement device’s operating manual. Use as short wires as possible. Make sure that the wires are not touching any undesired surfaces. Choose the adequate range and scale for the measurement.

- Clean the electrode with a dry, clean, and non-particulating towel.

- Carry out the measurement and record the results. Read the result when the reading is stable or 15s after applying a voltage to the measurement circuit.

- Repeat measurements at least five times. Record minimum and maximum values, and use the median as a measurement result.

- Record the environmental conditions, humidity, and temperature. Take also into account the possible conditioning of the sample before the measurement or how the sample has been stored 48 hours before the measurement.

The most important factor behind a good and reliable result is understanding the measurement setup and procedure. As mentioned before, the best measurement gives the smallest deviation in results. When presenting the results, make sure the measurement method and the measurement voltage are also described. This article has been written in cooperation with Toni Viheriäkoski from Cascade Metrology, an independent laboratory for electrostatic measurements and instrument calibration. Technical papers published by Cascade Metrology on resistance measurement have been used as source material. www.cascademetrology.com.

Pasi Seppälä

Product Manager - Conductive Plastics

M.Sc of polymer technology with an excellent balance of skepticism and understanding of polymer-related phenomena. It might not be a bad idea to contact him when in (technical) doubt.